Aftermarket Excavator Components to Optimize Your Construction Machinery

When it comes to taking full advantage of the performance and performance of your building equipment, discovering the realm of aftermarket excavator components can use a variety of advantages. These elements, created to perfectly integrate with your excavator, can present a cost-effective option to improve the capacities of your tools. From enhanced sturdiness to boosted performance, aftermarket components have actually gained popularity amongst construction professionals looking to optimize their machinery. However, before diving right into the globe of aftermarket alternatives, there are crucial factors to consider, brands, and setup techniques that can dramatically impact the outcome. As the sector continues to develop, understanding just how aftermarket excavator components can boost your building and construction jobs is necessary for remaining affordable and efficient in this dynamic field.

Advantages of Aftermarket Excavator Components

Using aftermarket excavator components supplies economical solutions for building machinery maintenance and fixing. These components are produced by third-party business and are designed to meet or go beyond the requirements of initial devices producer (OEM) parts. Among the key benefits of aftermarket excavator parts is their price. Compared to OEM components, aftermarket alternatives are commonly offered at a lower price point, enabling construction companies to lower upkeep and repair service costs without endangering on quality.

Additionally, aftermarket excavator components provide a bigger option and accessibility. With countless aftermarket providers in the market, building and construction business have access to a wider variety of choices to choose from, ensuring that they can discover the ideal component for their specific needs rapidly. This availability also helps in lessening downtime as components can be sourced a lot more efficiently.

Additionally, aftermarket excavator components are recognized for their high quality and dependability. Lots of aftermarket manufacturers stick to stringent quality assurance requirements to make sure that their parts perform well and have a long life-span. This dependability is vital for construction equipment that runs in testing environments and need to stand up to heavy use. Generally, the advantages of aftermarket excavator parts make them a sensible option for construction companies aiming to enhance their upkeep and repair service processes.

Elements to Take Into Consideration When Selecting Components

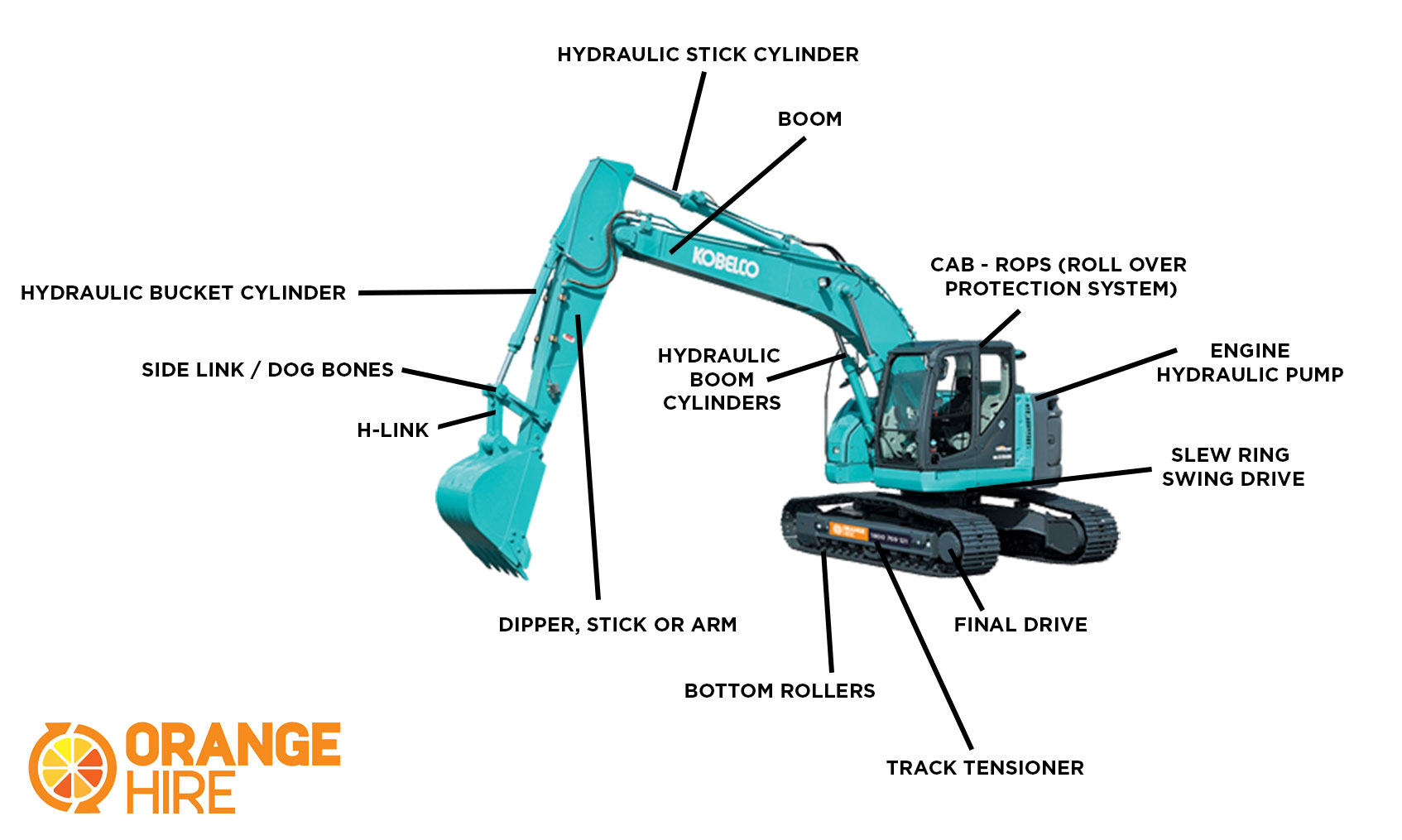

When picking components for building machinery, it is crucial to meticulously analyze compatibility with the details make and version of the excavator. One crucial element to think about is the top quality of the aftermarket components.

One more crucial consideration is the compatibility of the get rid of the existing system of the excavator. Ensuring that the aftermarket components effortlessly operate and fit with the initial tools is crucial to stop breakdowns, downtime, and prospective safety dangers. In addition, examining the service warranty and return plan offered by the parts distributor is necessary. A trustworthy warranty can provide peace of mind and protection in case of any defects or concerns with the purchased parts.

Moreover, evaluating the cost-effectiveness of the aftermarket parts is crucial. While rate is a considerable element, it is necessary to consider the total value and lasting benefits that the parts supply in regards to effectiveness, toughness, and performance. By very carefully considering these aspects, building specialists can make enlightened decisions when choosing aftermarket excavator components for their equipment.

Leading Aftermarket Brands for Excavators

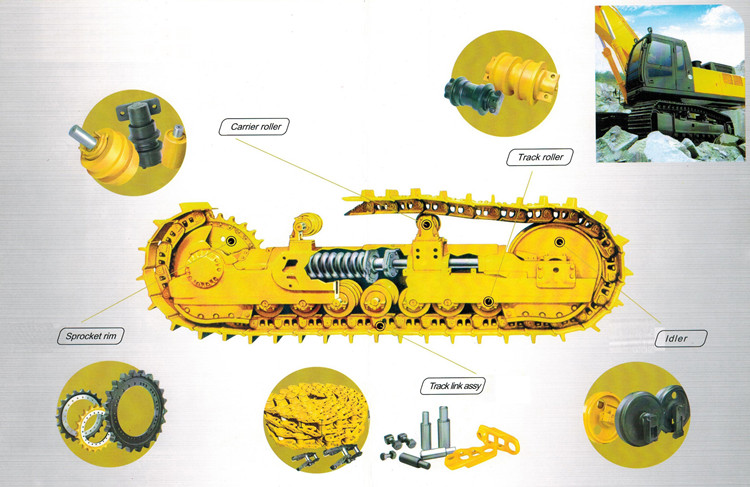

Analyzing credible aftermarket brand names for excavators can give building and construction specialists with reputable options for premium replacement parts. One such top aftermarket brand is Berco, recognized for its resilient undercarriage components that make certain ideal performance in demanding construction environments. An additional renowned brand name is Hensley, specializing in bucket teeth and adapters that use extraordinary toughness and durability. For hydraulic components like motors and pumps, firms commonly transform to Kawasaki Accuracy Equipment, recognized for its cutting-edge services and exceptional integrity. In addition, ESCO stands apart for its large range of ground engaging devices, including cutting sides and use components that improve excavation performance. Building and construction specialists additionally rely on ITR America for its detailed option of aftermarket components that guarantee compatibility and performance. By picking from these top aftermarket brands, excavator operators can properly maximize their construction machinery for raised performance and longevity on the job site.

Setup Tips for Optimum Efficiency

To achieve optimum performance and efficiency when setting up aftermarket excavator parts, thorough interest to information and adherence to supplier specifications are critical. When fitting the aftermarket excavator components, guarantee that each element is firmly secured my site according to the manufacturer's standards.

Additionally, it is necessary to examine the functionality of the excavator after mounting the aftermarket parts. Inspect for any kind of uncommon noises, resonances, or malfunctions that may indicate incorrect installment. Conduct a complete examination of the excavator's performance to verify that the new parts are functioning correctly and enhancing the device's performance. By adhering to these setup tips with accuracy and care, construction specialists can make sure that their excavators run at peak performance levels with aftermarket components.

Cost Cost Savings With Aftermarket Parts

While original equipment manufacturer (OEM) components are commonly viewed as the default choice, aftermarket parts use an even more economical alternative without jeopardizing quality. By opting for aftermarket components, construction business can delight in expense financial savings of up to 40% contrasted to OEM components, making it a functional selection for companies aiming to minimize upkeep expenses - aftermarket excavator parts.

Additionally, aftermarket parts are understood for their affordable pricing without compromising efficiency and toughness. Ultimately, leveraging aftermarket components can be a strategic strategy for building companies looking to enhance price savings in equipment upkeep and repair work.

Final Thought

To conclude, aftermarket excavator parts offer countless advantages such as expense financial savings and maximized effectiveness for construction equipment. When selecting components, consider elements like compatibility and top quality. Leading aftermarket brand names for excavators consist of credible suppliers understood for their reliability. Appropriate installation is important for taking full advantage of efficiency and efficiency. Generally, using aftermarket parts can cause considerable price financial savings while maintaining the performance and long life of your building and construction devices.

When it comes to making the most of the performance and effectiveness of your building and construction machinery, discovering the world of aftermarket excavator components can provide a range of benefits. These parts are produced by third-party business and are designed to meet or surpass the specs of initial equipment pop over here manufacturer (OEM) parts. While initial equipment producer (OEM) components are commonly viewed as the default option, aftermarket components offer a more economical option without compromising top quality. By choosing for aftermarket parts, construction firms can take pleasure in price financial savings of up to 40% contrasted to OEM components, making it a sensible choice for companies intending to decrease upkeep costs.